Thoughts and impressions from a stay in the polder area around Boskop in the Netherlands

Holland, also known for the canals and polders that extend over huge Reed areas. Land reclamation, water management is an issue that dominates and concerns people here, also necessary for survival in the future.

Here I can see a good source of renewable raw materials to produce biochar and energy .

Why not the production of biochar.

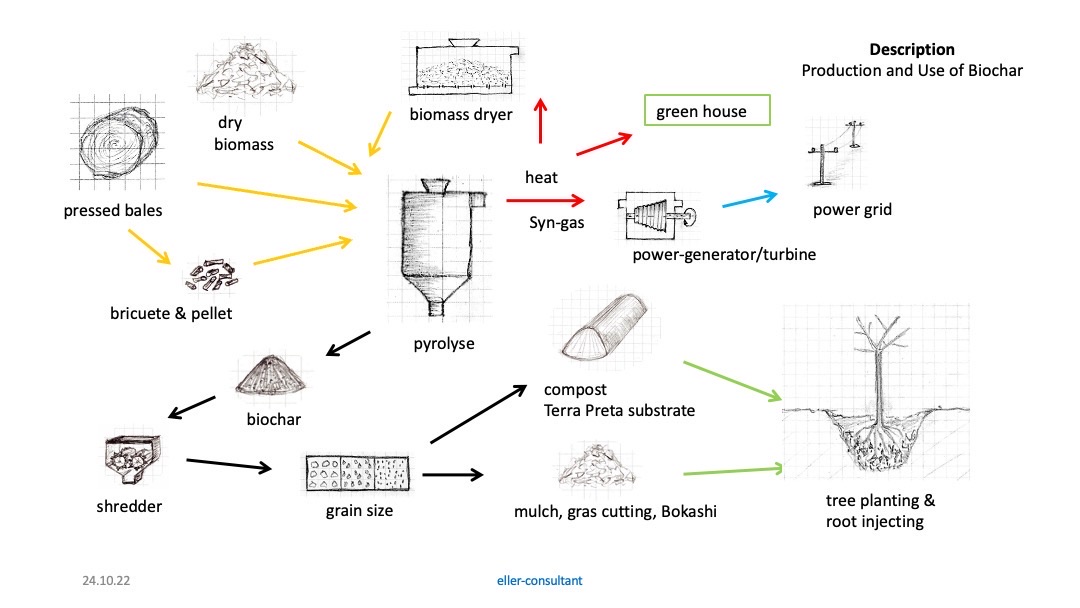

The grass in the form of hay could also serve as a basis for pellets, which can then be used for carbonization and/or heating.

The use of rolled bales would also be conceivable, which could then be converted directly into biochar in a pyrolysis batch retort.

Advantage: the collecting and press process is established, they are usually already dry and do not have to be extensively converted into pellets.

Some examples:

Biomass to Biochar from Irland. www.biomasstobiochar.ie

Metitron combined a harvester to press Pellets straight onto the filds.

www.metitron.de

Also the Institut ATB is researching and dealing with this idea.

Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB)

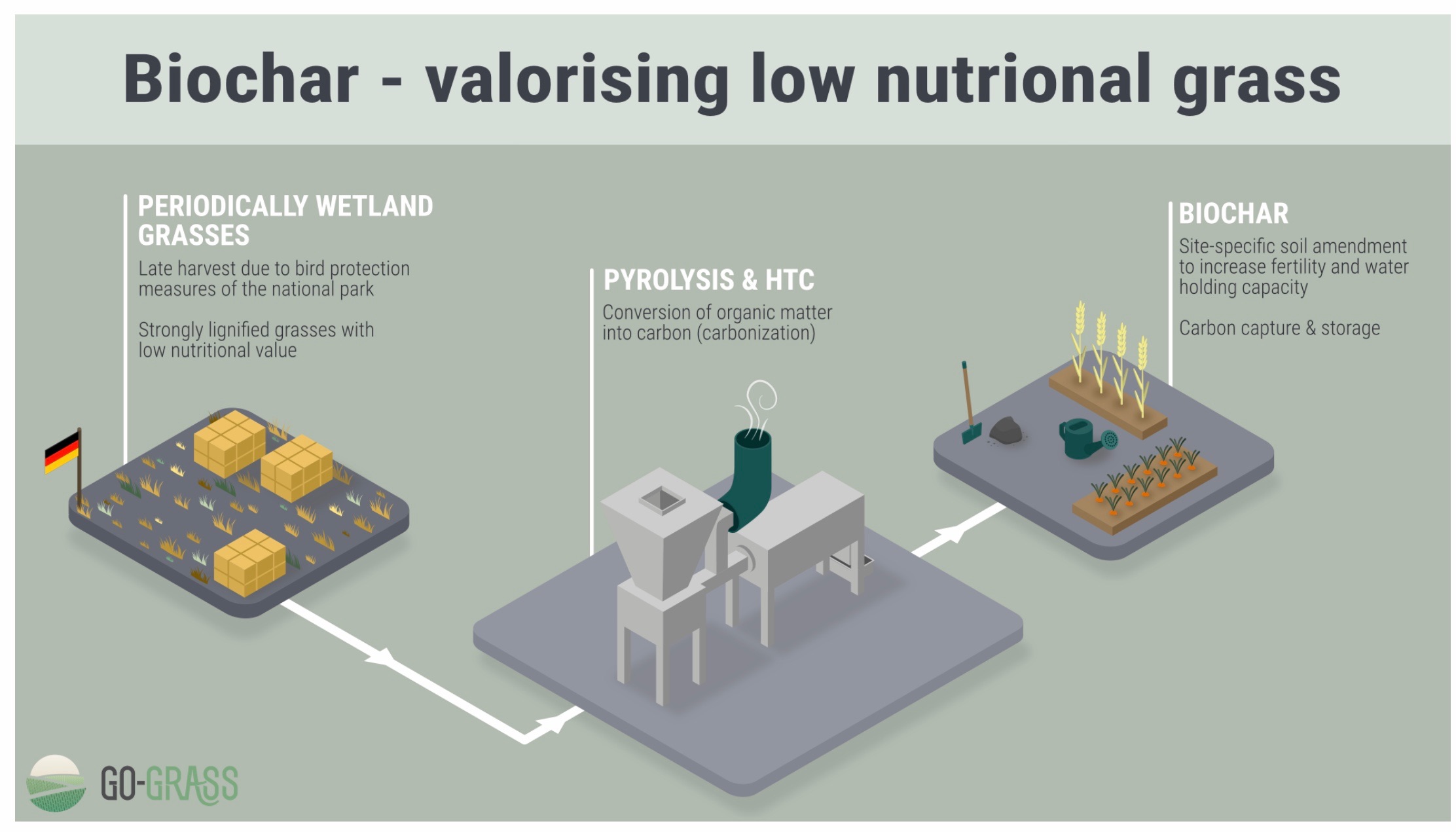

The Initiative Go-Grass shows a good example of utilisation of “grass“

www.go-grass.eu

Coupled with the countless greenhouses that are partly heated and the need for good soil, a good approach.

In conversation with an ornamental plant manufacturer

the topic of seasonal overproduction was also addressed, large quantities of biomass that must be disposed of.

Another current issue of Netherlands farmers is overfertilization with nitrate and the new strict regulation against high nitrates in groundwater.

Here is an excerpt from SWR3 from 07/16/2022

Why is there a farmers‘ strike in Holland?

The Dutch government wants to reduce nitrogen emissions by an average of half nationwide by 2030. A large part of the pollutants come from agriculture, so farmers‘ livestock is to be drastically reduced. In protest against this, farmers repeatedly block motorways.

Not only an issue in Holland.

Effects to be seen on the lush algae carpets on the canals.

Possible also, with the right application, the generating of C-capture certificates.

Purchasable e.g. at the DUTCH CARBONEERRS, CarbonFuture in Germany and others offer this service on the market already.

Possible Workshop’s on biochar in agriculture purposes

– What is biochar

– What characteristics does it have?

– Typical areas of application

– Production of biochar,

– open fire retorts,

– Closed batch procedure,

– Continuous processes

– Practical use in organic growth of biomass in Garden and Agreculture,

Possible scenarios for the small beginning.

There are sizes of 50-2500 liters of carbonizing space.

How to start biochar production and use of biomass as fuel:

– To start the process collect dry wood and produce biochar directly with e.g. a earth Kon-Tiki ore a small stainless steal retort.

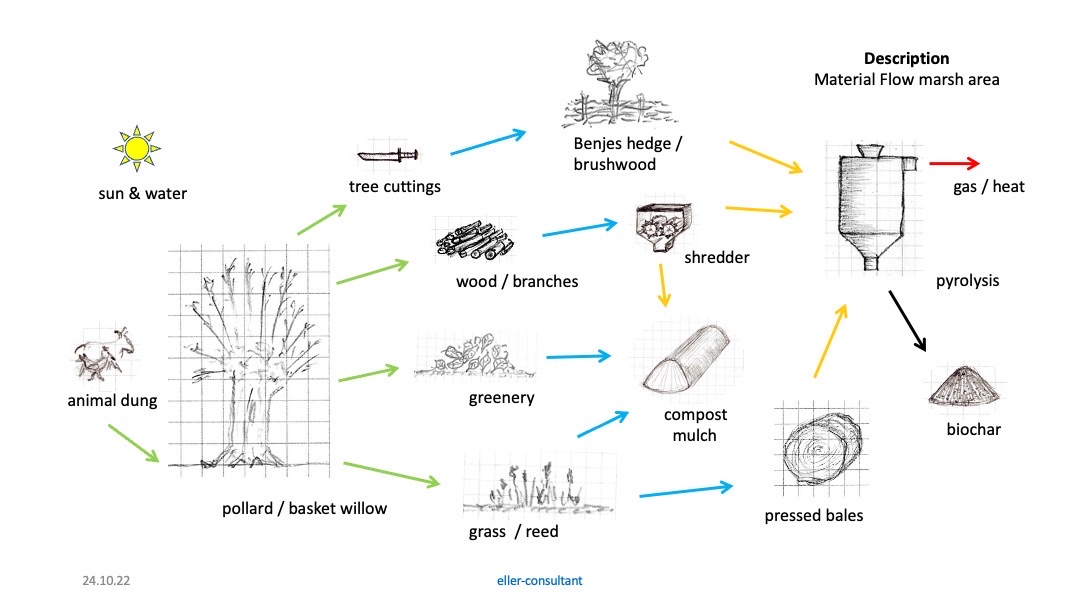

– To go for the next year cut existing willow trees etc. and place them in Benjes hedges for 1-2 years to dry or store them dry.

– Plant trees and hedges for harvesting in 3-5 years

When using Benjes hedges, material can be karbonisiert and simultan harvested and stored for the next year. The foliage and small branches can either go into compost production or they can be stay in place and they form humus and scrub for living beings.

On a large-scale point of view, the use of wood chips or pellets will make more sense.

In combination with drying in a container, through waste heat from the pyrolysis process and automatic supply and extraction.

In summer operation, due to the excess of heat, more wood chips or pellets material is dried and then has more waste heat for heating in winter operation.